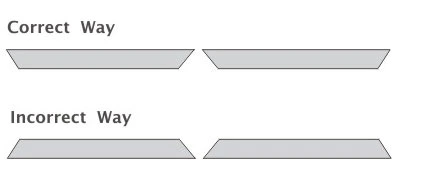

Which way up?

There seems to be some confusion about the way you lay natural stone. Please see the diagram as detailed below…

Getting ready to lay your patio

You will need

• Spade and/or shovel • Wheelbarrow • Lump hammer • Rubber mallet • Brick and/or pointing trowel

• Spirit level • Sweeping brush • String lines • Wooden pegs or steel pins for • Fastening line

• 2.4 – 3.6m long timber straightedge • Cement mixer • Protective gloves • Protective eyewear

Drainage

Flagstones need to be laid to falls to ensure that any water on the surface will drain away properly. We recommend a fall of 1:60, which is equivalent to 17mm per linear meter. This is sufficient to drain the paving without it being noticeably sloped.

Preparation

The area to be paved needs to be cleared of all vegetation and topsoil, to a depth of at least 65mm. Remember: paving should always be laid at least 150mm lower than the Damp Proof Course (DPC) of any adjacent building.

Use taut string lines as guides to both alignment and surface level. These can be fastened to pegs knocked into the ground or nails fixed into masonry. Use string lines at the edges of the pavement and then use a long timber straightedge to span from the flags to the string lines to check for level.

Mixing Mortar

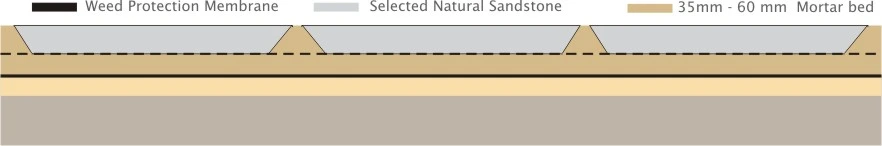

The flags need to be laid onto a full mortar bed. This means the bed underneath each piece extends beneath the entire flagstone, with no gaps or voids. Some less experienced installers lay flags onto ‘spots’ or ‘dabs’ of mortar, which we cannot recommend as these spots do not offer full support to the flags and often cause problems in the months ahead.

The mortar should be a mix of 4 parts sharp sand with one part cement, mixed to a consistency that is moist but not overly wet. Wet mortar can be messy. Light coloured flagstones, and those formed from granite are often prone to discolouration when laid onto mortars made using strongly-coloured sand, such as the orangey sands common in SE England. For these flagstones, we recommend that the laying mortar should be prepared using 6 parts neutral coloured sand (often sold as “Silver Sand”) and 1 part white cement. This will minimise any risk of discolouration whilst ensuring your new paving is properly bedded and fully supported.

The mortar bed should be 35mm to 60mm thick. Where the mortar would be thicker than this, or where levels need to be built-up, this should be done using crushed stone such as Type 1 which is readily available at most Builders Merchants. Aim to have a reasonably consistent bed thickness throughout.

It’s best to use a powered mixer to prepare the mortar. These can be hired locally for around £30 per week, if necessary. They make light work of the mixing and allow you to save your energy for laying the flags, rather than mixing sand and cement. Mix only as much bedding mortar as will be used in 30-60 minutes. Mortar starts to harden as soon as it is mixed and, in warm weather, it may become ‘stiff’ and unworkable in as little as 20 minutes.

Be sure to wear protective eyewear and gloves when mixing mortar. Cement is strongly alkaline when wet, so dust or mortar splashes can damage your eyes and your skin. Wear long sleeved clothing and wash any splashes with clean water immediately. You should wear protective gloves at all times, as they will help protect your hands from abrasion while handling tools and flagstones.

Laying your patio….

Cutting

If your patio involves a lot of cutting we would advise that you hire a powered cutting tool with a diamond tipped blade (any hire shop will advise you of the machine and blade you will need if you advise them of what you are intending to cut). Please take care and also make sure that your hire shop issues you will full instructions and relevant safety equipment, including goggles.

Selection

We recommend that whenever laying natural stone you should mix your paving from 3-4 different packs (where possible) as you lay your patio. This will allow the colours to blend and help to improve any shade variations that may occur between packs, giving your patio a more natural look.

Laying the flags

Using a brick or pointing trowel, spread the mortar over an area approximately 100mm longer and wider than the flag to be laid. Ripple the surface of the bed with the point of the trowel so that there will be some ‘give’ once the flag is placed onto the mortar.

Lift the flag into position and carefully lower it onto the bed. With larger flags (600x600mm or larger) it is best to have an assistant helping to lift and lower the flag. Once in position, the flag should be 5-10mm high, and should then be tapped down to the correct level using the rubber mallet.

Don’t hit the flagstone at the corners or in the exact centre. This can break the flagstone and, even if it doesn’t, it usually results in uneven laying. Aim for the points that are located roughly halfway between the centre and the corners, and use a succession of light but firm taps rather than heavy blows. Tap down one edge once or twice and then tap the opposite edge, alternating as required until the flag is at the correct level.

If the flag is not going down on the bed, you may need to lift it out and remove some of the bedding mortar. Take care not to allow the bedding mortar to stain the flagstone edges when lifting it from the bed. Similarly, if the flag goes down too far, you may need to add mortar to the bed to achieve the correct level.

Use the spirit level and/or the straightedge to check the flag is falling in the right direction and is at the correct level. Be certain that the flag is correct before moving on to prepare a bed for the next flag. Remember to allow for jointing. Many flagstones are laid with a 10-15mm wide joint that can be filled with mortar or a resin-based jointing material once the bed mortar has hardened (usually 24-48 hours). With some random layouts, you may find that some joints need to be 8-12mm wide while others are more like 15-18mm wide. This is nothing to worry about, but should be borne in mind when laying the flags. You may find that you need to adjust the width of some joints as the laying proceeds.

There should be no significant ‘lips’ between adjacent flagstones. They should be roughly (± 2mm) level with each other. At free edges of the paving (ie: where the flagstones would lie against grass or flower beds, etc.) you may wish to bring the mortar bedding up the edge of the flagstones to prevent them moving sideways.

Jointing

Traditionally, flagstones were pointed with a cement mortar. This would be made using a 3:1 mix of building sand (softer and less coarse than the sand used for the bed mortar) with cement, but as mentioned previously, when working with light-coloured sandstones and granites, it’s often better to use silver sand with white cement.

The jointing mortar is mixed to a stiffer consistency than bed mortar, and then pushed into the joint from the blade of a trowel using a small pointing trowel, packing it into the joint before smoothing off with the pointing trowel or a special ‘pointing iron’ that gives a flat or semi-round profile. This takes a great deal of care to ensure the mortar does not stain the edges of the flagstones and it can be very time-consuming for those not familiar with it.

Nowadays, many contractors use resin-based or polymeric mortars to joint flagstones. These are simply brushed into the joints, and any surplus swept off the surface. The resin is completely transparent, so cannot permanently stain the flagstones. Occasionally, a slightly shiny film or residue may be left behind on the flagstone surface, but this should weather away in a few days. These resin or polymeric mortars are more expensive than a sand/cement mortar, but they are very easy to use, very quick, and they avoid any risk of staining, even with light-coloured and/or granite flagstones, so may be worth considering.

Colour Enhancers and Sealants

Some homeowners prefer the look of their paving when it is damp or wet, as the moisture tends to bring out the natural colour of the stone. This effect can be achieved permanently by using a good quality colour enhancer. It’s worth noting that different types of stone look better with different colour enhancers, so try to choose a product that is specific to your material rather than a ‘jack-of-all-trades’. Always test the colour enhancer on a surplus flagstone or sett or in a discreet corner before applying it to the whole pavement. Allow it to dry and leave it for a few days as the character can often change as the product cures

While colour enhancer can improve the looks of the stone, sealants can both enhance the colour and protect the paving from accidental staining or colonisation by algae and lichens. There is a great deal of variety with sealants, both in terms of the type of chemicals used to manufacture them, and in their finished appearance.

It’s vitally important to appreciate that sealants should only ever be applied to paving that is bone dry. The presence of any moisture on the pavement surface or within the jointing can seriously affect the way in which the sealant cures, and in some cases, will result in an unattractive milky-white discoloration which can only be corrected by chemically stripping the sealant. Consequently, sealing should only be undertaken during the warmer, drier summer months. If the paving was laid during winter or spring, it may be a good idea to have it cleaned prior to sealing, but be sure to allow at least two days for it to thoroughly dry before applying the sealant in accordance with the Manufacturer’s instructions.

Strata Stones cannot accept any responsibility for any mortar staining, cutting or problems during the laying of their sandstone and limestone