Installation Instructions

The “FLEXSTONE” sheet is made from 2-4mm thick natural slate with a resin (polyester) and fiberglass back layer, which provides high resistance, flexibility, and dimensional stability.

It is a very versatile, lightweight, flexible product, and because it is so easy to install, it is ideal for refurbishments, as it prevents a large generation of debris, as well as for covering large areas. Due to its characteristics and stability, it is a product that holds very well, without deforming or cracking in both high and low temperatures.

In addition, due to its typology, it has a good bending radius without breaking, making it suitable for installing in curved places.

Technical Features

| Density | 822Ibs.per cu.ft. 16.02kg/m3 |

|---|---|

| Dimensions | 240 x 120cm / 120 x 60cm |

| Thickness | 0.2-0.4cm |

| Thermal conductivity | 1569k |

| Heat resistance | 1.148 R |

| Absorption | 1.9-2.5% |

Information to take into account before you begin the installation it is extremely important that you correctly read and understand the information given in these instructions before starting with the installation, as an incorrect installation, use, or maintenance of the installation may result in the cancellation of the manufacturer’s warranty.The points listed below are part of the installer/owner’s liability:

Carefully inspect ALL material prior to installation, to verify that it has no defects. Materials installed with visible defects are not covered by the warranty.

Exposure to direct sunlight or contact with water can produce tone changes over time, and slate, because the slate may contain oxide traces, it may present oxidation points on its surface when in contact with water. This is something inherent to slate and is NOT a defect.

- If you are not satisfied with the material prior to installing, please contact your dealer. DO NOT INSTALL IT.

- We recommend that, as a final inspection, you examine the color, finish, style, and quality, BEFORE installing. Verify that the material is right We will not be liable for any expenses incurred once the pieces with visible defects are installed.

- It is the installer’s and the owner’s responsibility to ensure that work conditions and the work area are suitable, before installing the material.

The installation surface shall meet the suitable characteristics for laying on a thin layer: clean surface, dry, rough texture with no ledges or loose parts, and above all flat (slope of 2mm with 2m ruler.)

- Check that the weather conditions are suitable for installing the materials.

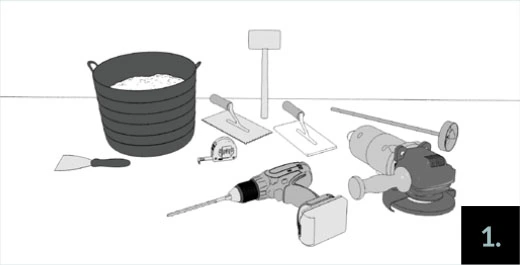

Installation

1 Subject to Conditions 6.2, 6.3 and 7.1, the following provisions of this Condition 9 set out the entire financial liability of the Company (including, without limitation, any liability for the acts or omissions of its employees, agents or sub-contractors) to the Customer in respect of: (a) any breach of these Conditions; (b) any use or resale by the Customer of any of the Goods or of any product incorporating the Goods; and (c) any representation, statement or act or omission (including any negligent act or omission) under or in connection with the Contract.

2 Before installing, protect the floor with cardboard or plastic to avoid stair’s.

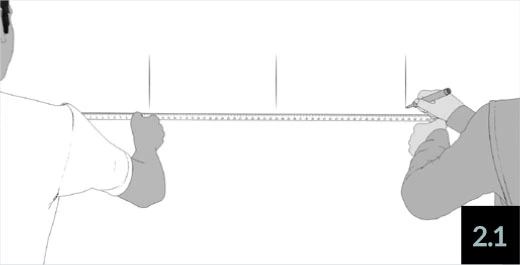

2.1 Next, knowing the sheet format, we shall mark the width and height measurements on the wall, to assist with its installation later. Cam/ out the construction layout, depending both on the wall the design and the use demands. Determine type and color of placement joints, cuts, and perimeter joints.

3 For installing the sheet, we recommend using masking tape placed on the end of the sheet to prevent the adhesive from depositing on the surface during installation, and to easily remove excess adhesive from the joints between sheets.

3.1 Check that the base or placement substrate is perfectly vertical, stable, non-deformable, and with no risk of water leaks and moisture in general. Initially place the sheet on the substrate and check that it is perfectly level.

3.2 For installing FLEXSTONE, we only recommend R2T reactive-resin adhesives as per EN 12004, such as BUTECH’s POUTECH PREMIUM.

Follow manufacturer recommendations in the preparation and use of adhesives. Do not apply adhesive with a final thickness greater than that indicated on the container.

Install the wall covering with the thin-layer method with adhesive and notched trowel no bigger than 8 x 8 mm, and use the double bonding method, which consists of applying the adhesive with the notched trowel on the substrate and applying an adhesive layer on the back of the piece with the smooth part of the trowel. Check that when you press the FLEXSTONE sheet on the adhesive, it does not overflow through the joint

3.3 Control the adhesive wettability, pressing the FLEXSTONE sheet on the bonding material, and check that the latter makes full contact with the back of the sheets. Once the adhesive is applied, lay the sheet with the hand and then use a trowel to extract the air from under the sheets.

3.4 Once the sheet is installed, it is very important to remove the excess adhesive immediately so prevent it from leaving residue on the surface. Clean thoroughly with a damp cloth or paper and let dry.

Installation Joints

– For installing outdoors:

Installation joints shall be 1mm at least We recommend covering the top of the facade with a trim that prevents the penetration of water.

Use CG2WA-type cement-based joint materials, such as BUTECH’s COLORSTUK RAPID N. We recommend using quick-setting and waterresistant joint mortars.

Apply the joint material with a rubber trowel, avoiding the formation of cracks or gaps, and clean before the contact of the joint mortar with the FLEXSTONE sheets may damage the wall covering or cause moisture stains.

To seal the joints, we recommend protecting the sides of the joints with masking tape to avoid staining the material with the product being used to seal the joint.

– For installing indoors:

Leaving joints is not necessary for its installation, they can be installed with butt joints.

If you decide to leave a joint we recommend using CG2WA cementbased joints such as Butech’s colorstuk rapid n.

Movement Joints

Observe the structural joints present in the substrate.

There will be perimeter joints in corners, wall covering changes in plane, and changes in material.

The intermediate movement joints shall configure panels as regular and square as possible. Place a horizontal movement joint at the bottom line of the floor slab of each floor. Do not carry out vertical movement joints separated more than 7 m. with a minimum width of 8 mm.

– Outdoors: Use elastic putties such as BUTECH’s p-404.

– Indoors: Use elastic silicone putties such as BUTECH’s s-107 N or p-404.

Protect the facade support from adverse weather conditions and other construction works that might damage it.

Efflorescence arises naturally from any mortar containing Portland cement If efflorescence appears, clean with a brush and a suitable detergent

5.1 The material is supplied protected, and it is therefore not necessary to apply any water-repellent after its installation. If you want to apply protector again, we recommend the use of a neutral protector such as FILA FOB. After applying the protective liquid, remove excess with a cloth or paper to make the application uniform.

Cutting and machining

Prepare a flat and clean space for making cuts

Dry drill FLEXSTONE pieces with drill bits of up to 8mm in diameter. For larger apertures, use drill bits for dry cutting porcelain.

Machine the pieces on the back with radial dry cutting machines and cutting disc for multiple materials.

Once the cuts are made, polish the edges with an abrasive block.